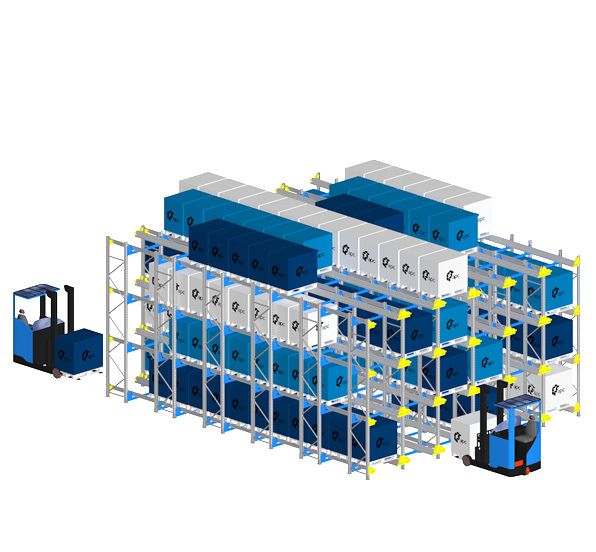

Radioshuttle Satellite Racking

Radioshuttle is a storage system that combines extremely high storage density with improved pallet and pick face access. Offering First in, First out and and First In, Last Out pallet movement via a remote-control Radioshuttle satellite.

APC have partnered with Radioshuttle, the industry leader in high density, semi automated satellite racking. The racking system is designed with tapered side rails to allow for easier forklift loading of the Radioshuttle satellite unit. Due to the semi automated satellite design the trucks do not have to enter the racking system so the risk of rack damage from the forklift is virtually eliminated. Radioshuttle utilises the entire volume of a warehouse, while offering efficient and economical pallet access and storage.

Colours

Custom colours available upon request.